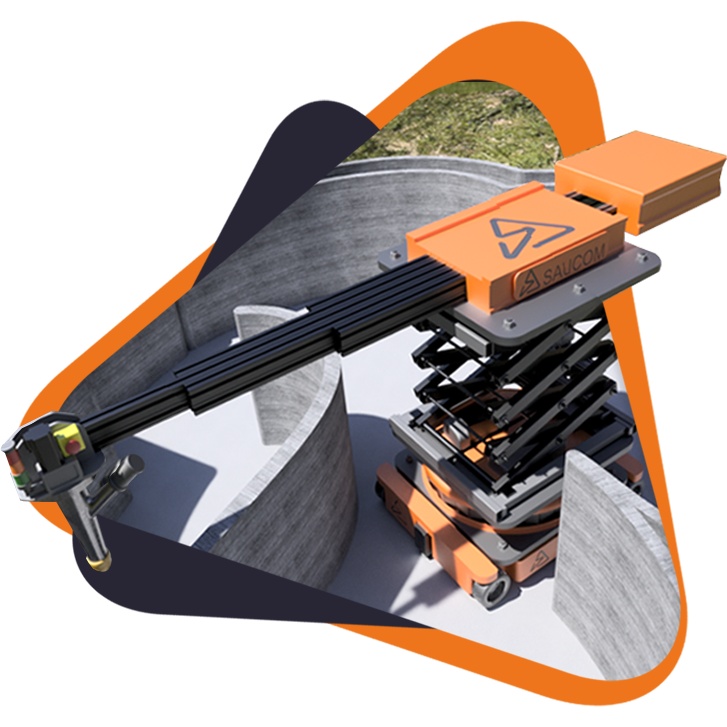

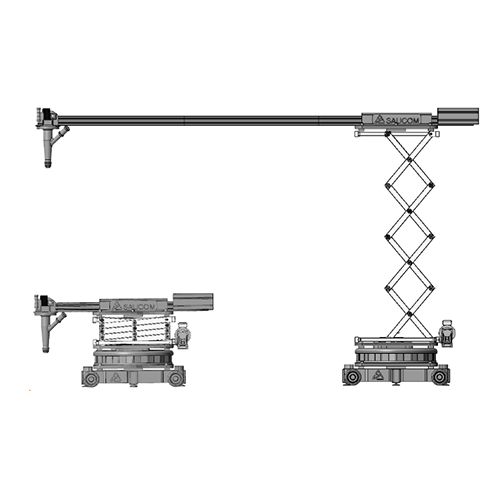

STORK V1 is a machine designed to 3D print concrete elements and design constructions. The innovative solution of the automatic construction machine consists of several modules and it is designed for efficient work on various types of projects. Fast setup and calibration, minimal dimensions and low weight for transport are an advantage.

Machine modules are available in various technical designs. It is possible to choose from an economic or complex solution. The modules are connected via a quick-release interface allowing easy replacement of any part. Individual modules can also be purchased separately and thus immediately expand the capabilities of your machine.

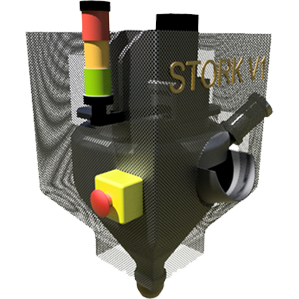

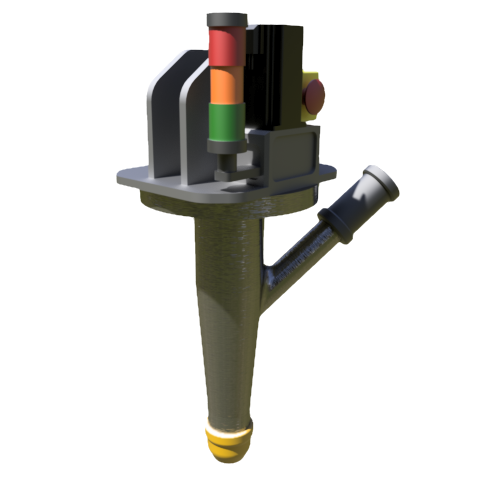

In manual mode enables manual material feeding.

In semi-automatic mode it sends a signal to the pumping device to fill in the material bin. It has a safety STOP button and a light to signal the amount of material in the magazine.

It is used in combination with an automatic pumping device that is controlled by a main system. It includes a safety STOP button and a signal light.

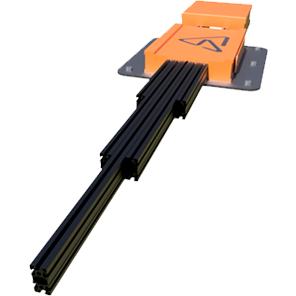

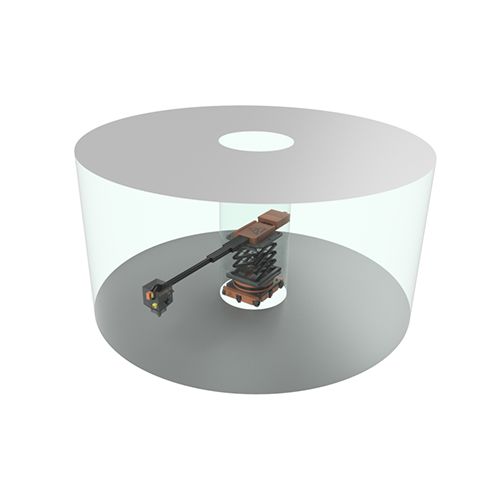

The basic solution of a rotating arm with a reach of 2 meters from the axis of rotation. This will create a printing space with a diameter of 4 meters.

Robust arm module with a reach of 3 meters from the axis of rotation. The telescopic concept ensures rigidity on a printing area with a diameter of 6 meters.

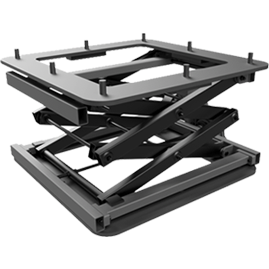

The 1.5M scissor lift mechanism allows printing of objects up to 1.5 meters high.

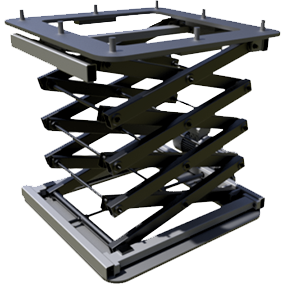

The 3M scissor lift mechanism is rigid enough for printing objects up to 3 meters high.

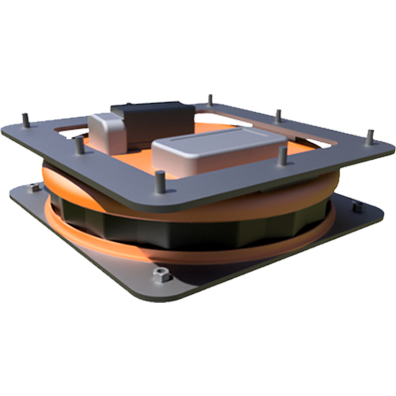

The core of the system is made up of a rotating mechanism that is the same for every STORK V1 combination. Allows rotation from 0° to 360°.

The solid base consists of a concrete core, which gives the system sufficient stability. Slots for pallet truck rails allow easy transport.

The wheelbase is controlled via a control system. Allows moving and turning in all directions. The automatic setting system settles the STORK V1 in the place selected for printing.

Compact dimensions for transport or relocation within the construction site.

The printing space has cylindrical shape with dimensions according to the selected machine design.

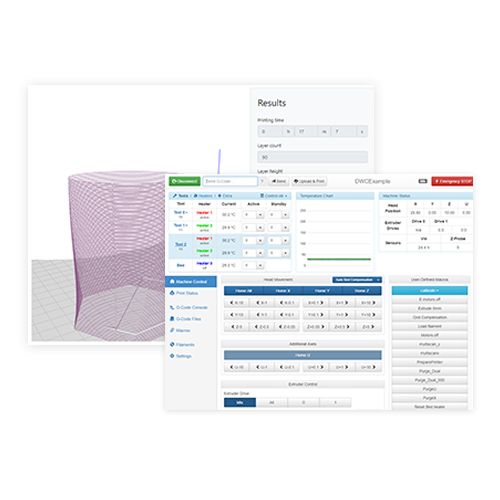

Software for models preparation before printing and control software for controlling the machine during printing.

Fully automatic mixing and material flow control, including mixture consistency control.

Manual mixing and automatic feeding the material to the machine print head.

Manual mixing and also feeding the material to the machine print head.

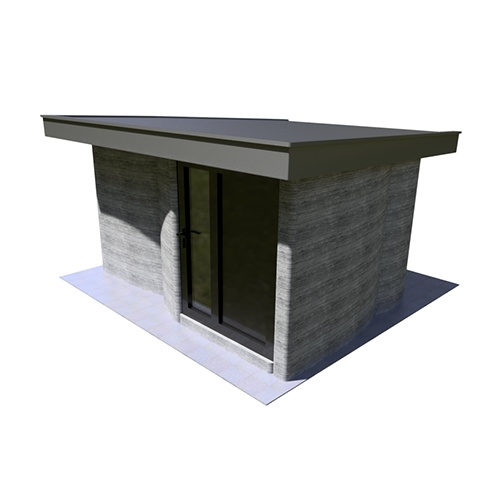

Design urban equipment, garden elements

Artistic and design objects

Small structures, garden sheds, design construction elements

Are you interested or have a question about STORK V1? Contact us via our contact form.